We are specialized in the production of customized sheet metal panels, made with flexible and cutting-edge systems.

The panels can be insulated with polyurethane, mineral wool, sheet foam and much more.

Some fields of application for the product are:

- UTA air handling units

- Ovens and painting booths

- Industrial refrigeration

- Soundproofing of industrial plants

The panels are produced on an automatic line that allows the continuous cutting and folding of the panels without intermediate handling and without the need for manual operations.

The high automation allows to obtain custom-made panels (width, length and thickness) with a low incidence of setups (times and therefore costs) for product change and high precision (narrow dimensional tolerances). The aesthetics of the product is also clearly superior to discontinuous cutting and bending solutions since the semi-finished products do not have to be stored and then moved between the processing stages.

Using our line it is possible to produce panels from very small (250 mm in length) up to very large, i.e. over 3 meters. The qualitative result is excellent regardless of the size of the piece.

Versions

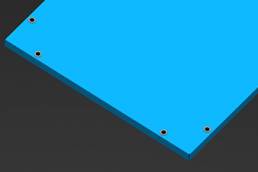

Flat panels

Panels composed of 2 sheet metal pieces with simple folds on 4 sides assembled by interlocking. Insulating material completely contained between the sheets. Available thicknesses compatible with aluminum profiles for the HVAC sector (15-20-23-25-46-49-50-60mm). Other thicknesses on request.

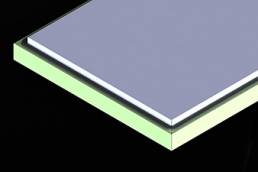

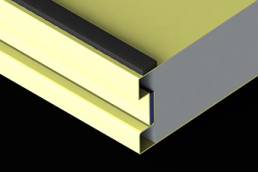

Step panels for thermal break alu profiles

The step between the internal and external part of the panel allows the product to be used in combination with the HVAC thermal break profiles available on the market.

Special construction panels

Panels made to satisfy customer specifications can be made with considerable construction complications such as to allow assembly without further structural elements (joints, deep drawing, fixing seats with threads…).

Insulating materials

Polyurethane

Rigid polyurethane foam, injected discontinuously under hot press. Average density 40-45 kg /m^3.

Excellent thermal insulation and high mechanical stability of the panel.

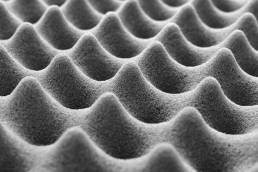

Mineral wool

Mineral wool obtained from cut block, oriented fiber with standard density 90-100 kg / m^3.

Excellent sound insulation and thermal insulation performance.

Other insulating materials

Insulating materials for specific applications such as expanded polystyrene, calcium silicate sheets, wood fiber and much more.

Optional services

Thixotropic gasket

A thixotropic polyurethane gasket can be applied to all types of panels.

The gasket is made directly on the panel by means of a robotic dosing system, with constant quality and without any junction point.

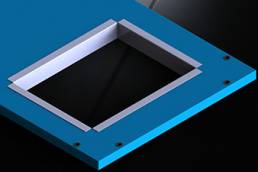

Custom made cuts

For the subsequent passage of pipes or for housing components (fans, measuring instruments, control panels …) it is possible to make polygonal or circular cuts. The cutout edges can be protected with sheet metal frames so that there is no visible insulation material.

Door holes

It is possible to customize the panels by adding custom made holes, for example to apply handles, hinges, portholes … The drilling patterns are compatible with the accessories normally used for UTA panels (air handling units), considerably simplifying panel assembly operations.

Thermal break

To avoid thermal bridges between the internal and external surface of the panel, it is possible to insert a thermal break inside the panel in order to thermally separate the two faces.

Accessories assembly

We can carry out the assembly of accessories accompanying the panel, such as portholes, hinges, handles and much more

Materials

The metal structure of the panels can be made with a wide range of raw materials depending on the final application of the product:

- Galvanized steel

- Pre-painted steel

- Plasticized steel (PVC coated steel)

- Aluminum/Peralluman

- Stainless steel

- Powder/liquid coated steel

Pre-painted and pre-plasticized materials are available in a wide range of colors. A peelable protective film is usually provided to protect the surface from scratches and dirt.

If a special non-catalog color is required, we have the possibility of obtaining the result by painting the raw material.

Pre-painted steel colors

White RAL 9010

White RAL 9002

Grey RAL 7035

PVC coated steel colors

White 01

Grey 85

Grey 01

Grey 14

Blue 01

Sand 03

Green 01

Red 02

Other colors are available on request.

Antimicrobial steel

Air treatment systems and industrial plants often have parts that are not easily accessible. The reduced cleaning could cause the spread of bacteria and the appearance of fungi, mold, algae and even unpleasant odors.

The ANTIMICROBIAL STEEL offers an effective and certified protection (ISO 22196: 2011 standard) against a vast panorama of micro organisms, including:

- Escherichia Coli;

- Staphylococcus Aureus;

- Staphylococcus Aureus Methicillin Resistant (MRSA);

- Klebsiella Pneaumoniae;

- Salmonella Typhi;

- Enterococcus Faecalis;

- Pseudomonas Aeruginosa;

- Legionella Pneumophila.

The product maintains its properties unaltered over time and does not require maintenance.