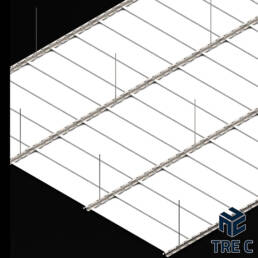

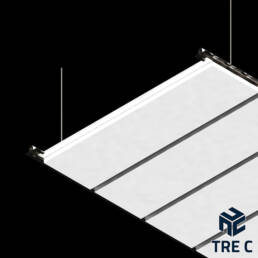

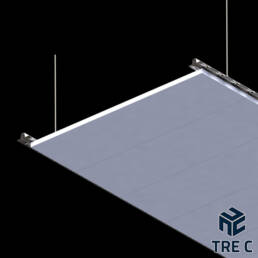

The MARINE BL false ceiling system is made up of metal panels supported by a hidden modular structure, designed for use on boats.

The system guarantees excellent surface flatness, maximum flexibility of use and durability of the product.

Main advantages

- Ease of cleaning

- Flexibility and ease of assembly

- Inspectability of the technical compartment above in case of maintenance

- Blades in standard version or with shutter

- Possibility of creating widespread ventilation using the ventilated blades

- Possibility to perform any drilling during production for the passage of ducts or for the installation of ceiling devices, such as: sprinklers, speakers, ceiling lights…

Certifications

MARINE BL CEILING SYSTEM is CE certified (MODULE B)

MED item 3.18a category USCG 164.112

MARINE BL CEILING SYSTEM false ceiling has obtained the CE CERTIFICATE FOR PRODUCTION QUALITY GUARANTEE (MODULE D)

Test standards:

- IMO Res. MSC.307(88) – (2010 FTP Code) Annex 1 Part 5

- SOLAS 74 Reg. II-2/3, Reg. II-2/5, Reg. II-2/6, Reg. X/3, IMO Res. MSC.36(63)-(1994 HSC Code) 7, IMO Res. MSC.97(73)-(2000 HSC Code) 7, IMO Circ. MSC 1120

References:

- Certificate number: MED/0497/1447

- US Coast Guard Module B: 164.112/EC0497/1447

- Module D: MED/0497/1530

Available formats

Blades

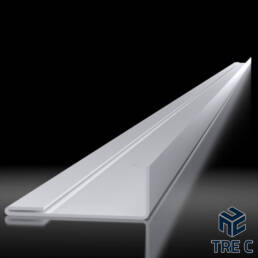

Blind version

Width 200 | 300 mm

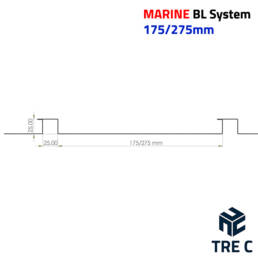

25mm shutter version

Width 175 | 275 mm

Ventilated 25mm shutter version

Width 175 | 275 mm

Length: from 600 to 3000 mm

Materials

- Aluminum 5/10 – 1.60 kg/m2

Aluminum 6/10 – 1.95 kg/m2

Aluminum 7/10 – 2.25 kg/m2

Steel 5/10 – 4.60 kg/m2

Steel 6/10 – 5.55 kg/m2

*Theoretical weights for standard non-perforated blades

Mounting systems

Standard blade200/300 mm

Blades with gap175/275 mm

Ventilated blades

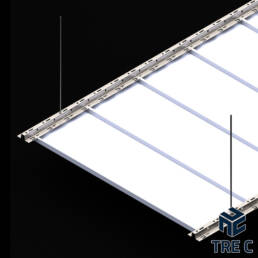

The MARINE BL false ceiling blades with shutter can be made in standard or ventilated version.

The ventilated blades has a linear slot in the upper part of the shutter.

The main advantages of diffused air flow are: fewer air currents, aesthetic uniformity and energy saving.

Blades with gap 25mm

Blades with gap 25mmVentilated version

Perforations

The false ceiling panels can be supplied in solid sheet metal or, if there are specific aesthetic or functional needs, also in perforated sheet metal.

Where necessary, a sound-absorbing layer of non-woven fabric can be applied.

This material offers several advantages:

- Effective sound absorption

- Pleasant aesthetic impact

- Environmental compatibility thanks to the absence of harmful substances

- It is not flammable

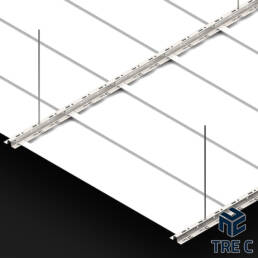

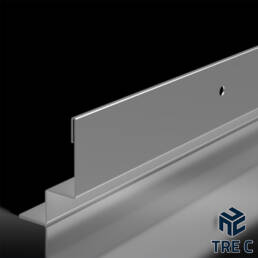

Modular structure

The modular structure of the system allows the false ceiling to be assembled quickly and easily, with few components normally available in stock.

Special executions

It is possible to carry out any customization, in terms of materials, workmanship and construction characteristics on standard products. Thanks to a flexible production system, we can supply batches with low numbers for each variant or size.

Product traceability

The product packaging contains the production batch data and all the characteristics of the false ceiling.

This allows you to easily identify the components during the system assembly phase.

Mounting accessories

The system includes a complete choice of accessories to allow the panels to be quickly assembled.

Interlocking primary structure

Item: NAV_BL_CARRIER

Material: Galvanized steel

It constitutes the load-bearing structure of the NAV-BL blades.

The blades are fitted into the profile using tabs.

L-shaped perimeter trim

Item: NAV_PFL_20_55

Material: Painted steel

Allows the perimeter support of the blades and their locking by means of a dowel spring.

Double "L" perimeter trim 20x20-55

Item: NAV_PF2L_20-20_55

Material: Painted steel

Allows the perimeter support of the blades and their locking by means of a dowel spring. Version with gap at the wall.

Double "L" perimeter trim 20x20-55 AIRGAP

Item: NAV_PF2L_20-20_55_AG

Material: Painted steel

Allows the perimeter support of the blades and their locking by means of a dowel spring. Version with gap at the wall. The slits allow the passage of air between the room and the cavity.

Color collection

Metal Ceiling Panels: Elegance and Customization for Every Environment

Metal ceilings are a modern and versatile solution for interior design, combining aesthetics and functionality. Among the different options available, metal panels stand out for their elegance and refinement, adding a touch of class to any environment.

Wide Range of Standard Finishes

To meet the most diverse needs, we offer a wide range of standard finishes for our metal ceiling panels. From classic and sober finishes to more modern and sought-after ones, you can choose the solution that best suits your style and taste.

Materials: galvanized steel, AISI 304 and AISI 316 stainless steel.What are the differences?

Galvanized steel, AISI 304 steel and AISI 316 steel are all strong and versatile metals that are used in a variety of applications. However, there are some key differences between these materials that are important to know to make the right choice for each project.

Galvanized steel

Galvanized steel is a type of steel that has been coated with zinc to protect it from corrosion. The galvanizing process is an electrochemical process in which zinc is deposited on the surface of the steel. Zinc is a very reactive metal and forms a protective film on the surface of the steel which protects it from atmospheric agents.

Galvanized steel is a relatively cheap and easy to find material. It is also very durable and can last for many years. However, galvanized steel is not resistant to all types of corrosion. It is particularly vulnerable to galvanic corrosion, which occurs when two dissimilar metals are in contact with each other in a humid environment.

AISI 304 steel

AISI 304 steel is a type of stainless steel that contains at least 18% chromium and 10% nickel. Chromium and nickel form a protective film on the surface of the steel which protects it from corrosion.

AISI 304 steel is a very versatile material that can be used in a variety of applications. It is resistant to corrosion, rust and scratches. It is also easy to clean and maintain.

AISI 304 steel is a more expensive material than galvanized steel, but it is also more resistant to corrosion. It is a good choice for applications that are exposed to harsh atmospheric conditions or corrosive substances.

AISI 316 steel

AISI 316 steel is a type of stainless steel that contains at least 16% chromium, 10% nickel and 2% molybdenum. Molybdenum improves the corrosion resistance of AISI 316 steel in marine environments, where chlorine is present.

AISI 316 steel is a very corrosion-resistant material. It is a good choice for applications that are exposed to harsh weather conditions, such as coastal or industrial areas.

Conclusions

If you need an inexpensive, easy-to-find material that is resistant to general corrosion, galvanized steel is a good choice. If greater corrosion resistance is needed, AISI 304 steel or AISI 316 steel is the best choice. In a marine or industrial environment, AISI 316 steel is normally recommended.