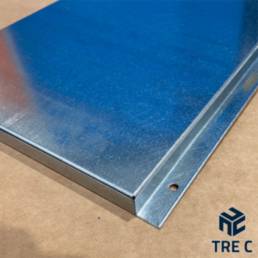

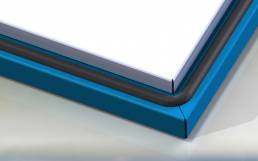

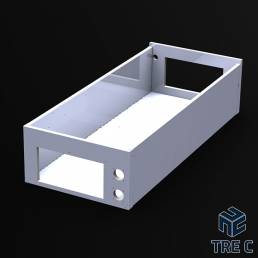

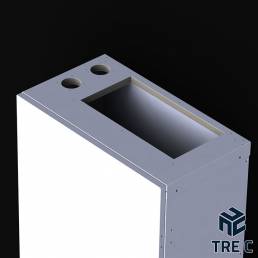

Custom made Sandwich panels, consisting of two sheet metal boxes assembled one inside the other. Insulation obtained by injection of polyurethane with an average density of 40-45 kg / m^3.

Possibility of making various holes according to drawing for the subsequent application of handles, hinges, portholes…

Advantages

- Uniform and continuous thermal insulation on the whole panel

- Acoustic insulation – the sandwich structure of the panels (sheet / polyurethane / sheet metal) and the high density of the foam ensure good sound insulation performance

- High resistance and durability guaranteed by the panel structure made with containment sheets

- Aesthetic result – a wide range of colors and surface finishes always allows you to obtain the desired final effect

- Cost containment – the use of pre-finished panels prevents the customer from investing in expensive machinery for sheet metal processing and foaming

Some possible applications

- Refrigeration appliances

- Air handling units HVAC

- Industrial plants

Technical features

- Available versions: SIMPLE type sandwich panel – STEP type sandwich panel

- Dimensions: Up to 3000 × 1500 mm

- Panel thickness: Standard 23-25-40-46-60 mm. On request up to 100 mm

- Sheet thickness: From 0,5 to 1,5 mm

- Materials: Galvanized sheet, plasticized / pre-painted, aluminum, stainless steel

- Average Foam Density: 40-45 kg / m^3

- Fire reaction: Class B s3, D0 [UNI EN 13501-1]

Insulating panels

PolyurethaneMineral woolOther insulating materials

Accessories

Trays

Catalogs

Insulating panels